Responding Quickly to your Flat Forms Spring Needs

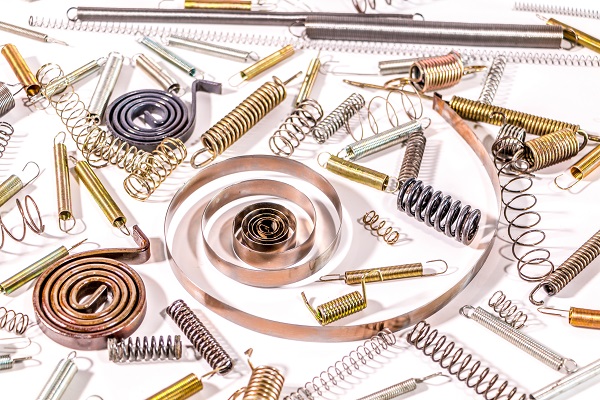

Flat forms spring is a type of spring made up of flat stock, sheet, or strip material. Flat springs come in different forms and sizes, depending upon its application or use. It finds its use in a number of products such as leaf springs, clock springs, clips, beam springs, and battery contacts. These springs do not have any standard shape or size. They are manufactured as per the requirement of different functions and applications. SMSC offers a wide variety of custom flat forms springs in various dimensions. These springs are essential components, which support the manufacture of a number of products. We have the right technology, equipment, and team that helps customers fulfill their design requirements with ultimate accuracy.

Flat Forms Spring Specifications:

Following are the specifications of these springs:

| Length of Legs | up to 24 in | up to 609.6 mm |

| Wire Size | .010 to .375 in | .254 to 9.525 mm |

| Direction of Winding | Right Hand | Left Hand |

| Material | Titanium | High Carbon Steel |

| Inconel® | Low Carbon Steel | |

| Monel® | Nickel Plated Carbon Steel | |

| Hastelloy® | Stainless Alloys | |

| Elgiloy® | Non-Ferrous Metals | |

| Finish | Plain | Black Oxide |

| Painted | Cadmium | |

| Passivate | Zinc Gold | |

| Zinc Silver | ||

Advantages of Using Flat Forms Springs:

Following are some of the major advantages of flat forms springs, due to which they are highly preferred in most of the industries:

- Used in a wide range of industrial applications: These springs are extensively used in a number of industrial applications such as military industries, mining, electronics, power generation, telecommunication, construction, medical and more. We can help you with designing customized springs in different dimensions based on your requirements.

- They are robustly built: When compared with round wire springs, flat forms springs are robustly built, and can sustain high impact loads. These springs are robust owing to the materials used in their manufacture. The robustness of these springs add to their durability, thus making them the first choice in demanding industrial applications. There is no compression or stretching involved in the manufacture of these springs, which reduces the risk of friction, buckling, and breakage.

- Saves lot of space with reduced spring length: These springs have reduced spring length, which helps save a lot of axial space in several applications. These springs save 50% more space as compared to that of conventional coil springs. Though the spring has reduced length, it does not compromise on load or spring deflection. Because of the reduced spring length, and a loftier surface area between coils, it makes these springs the first choice for applications having space constraints.

Applications of Flat Forms Springs:

Following are some of the major applications of flat forms springs:

- Collars

- Simple Beams

- Clips

- Specialty Formed Bus Bars

- Hangers

- Brush Holders

- Latches

- Fuse Holders

- Braces

SMSC has specialized in producing high quality custom flat forms springs for more than seven decades. We have proven technical expertise and industry knowledge to meet the requirements of a wide variety of industries. We provide flat forms springs that not only meet, but exceed the customers’ expectations. Get in touch with our professional for any queries or inquiries related to different types of springs. You can reach out to us via phone on 800-330-2460 or mail us at smsc@windstream.net.

Upload Your CAD Drawing

Upload Your CAD Drawing